About Us & Why We are

The Best For the Job

L.E.F., INC. is a multi-service facility specializing in laser processing and metal fabrication. We were the first company in 1987 to introduce the Tulsa area to laser technology. Today multiple processes are performed under one roof including laser cutting, laser marking, bending, roll forming, machining, welding, powder coating and wet painting.

We have the highest power and most automated equipment available. This allows us to be the most competitive laser operation in terms of cost and quality in our industry. We can laser cut sheets as thin as .005 and over 1” thick.

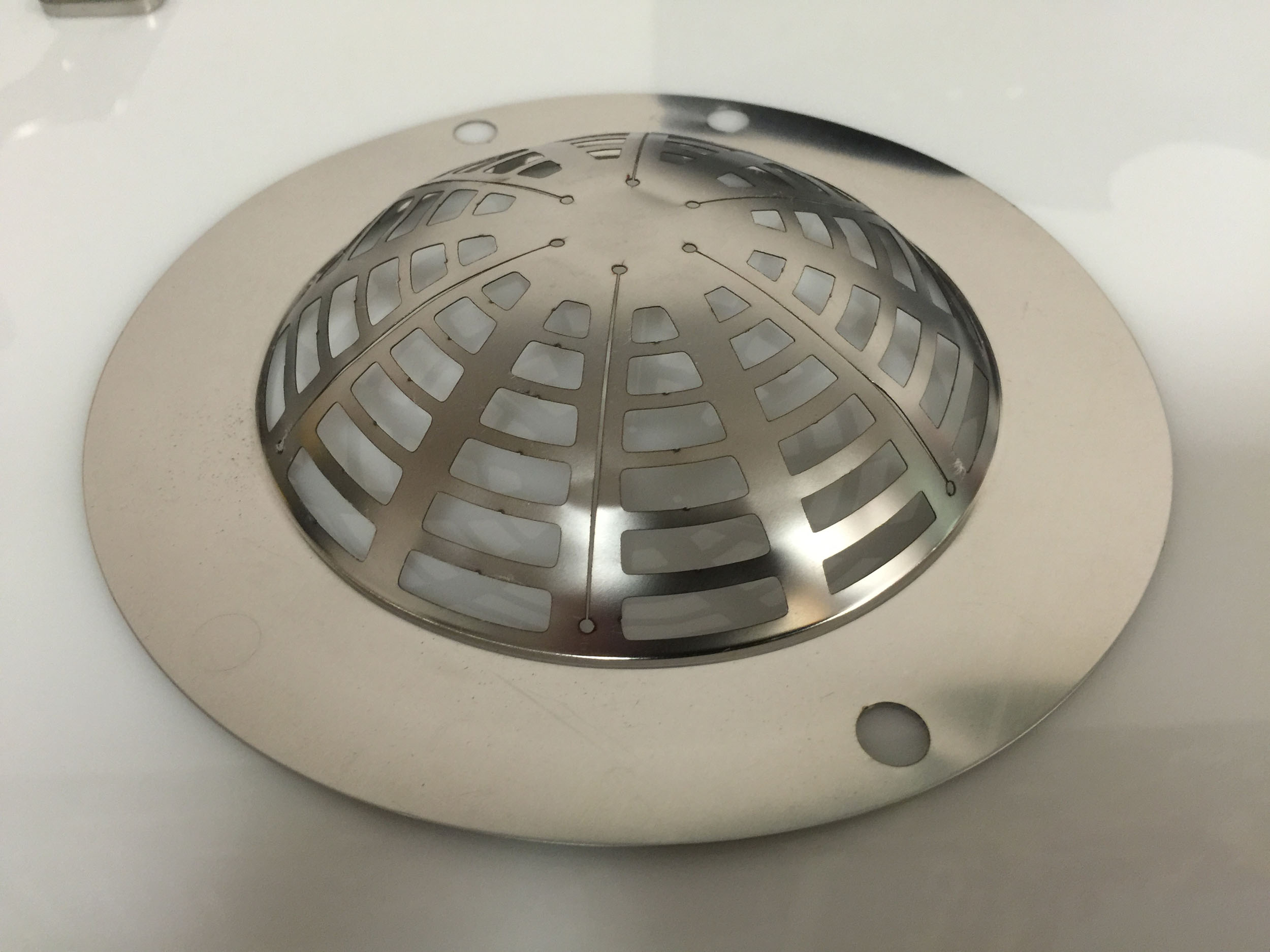

3 AXIS LASER

Lasers are an exact, high-speed, computer controlled alternative to stamping, cutting or processing by other means. Our precise, computer controlled lasers focus light energy into an extremely thin cutting beam.

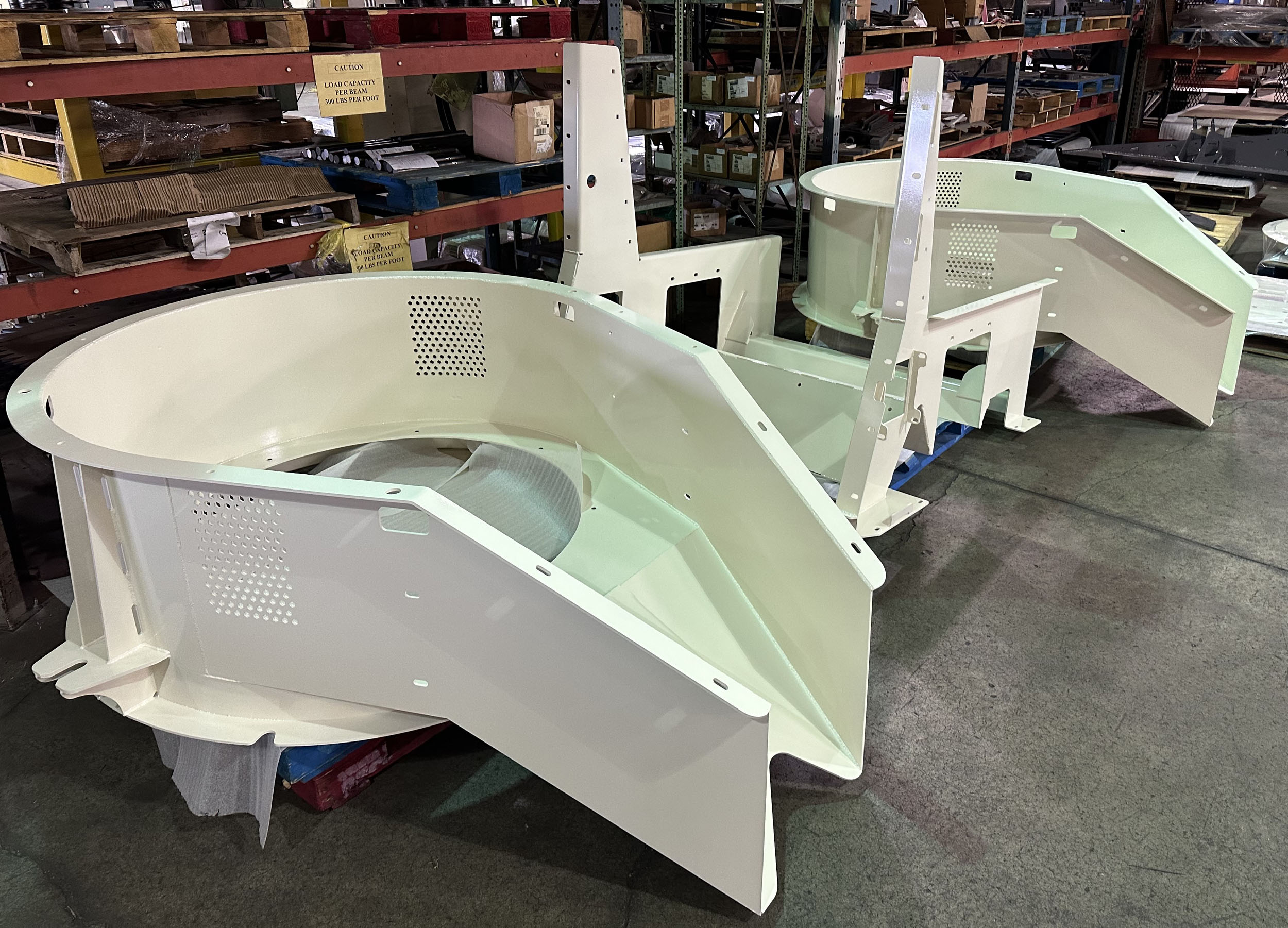

5 AXIS LASER

L.E.F., INC’s 5-Axis laser cutting systems simplify the cut process of 3-dimensional parts. We can run G code programming or utilize the laser manufacturers proprietary coding.

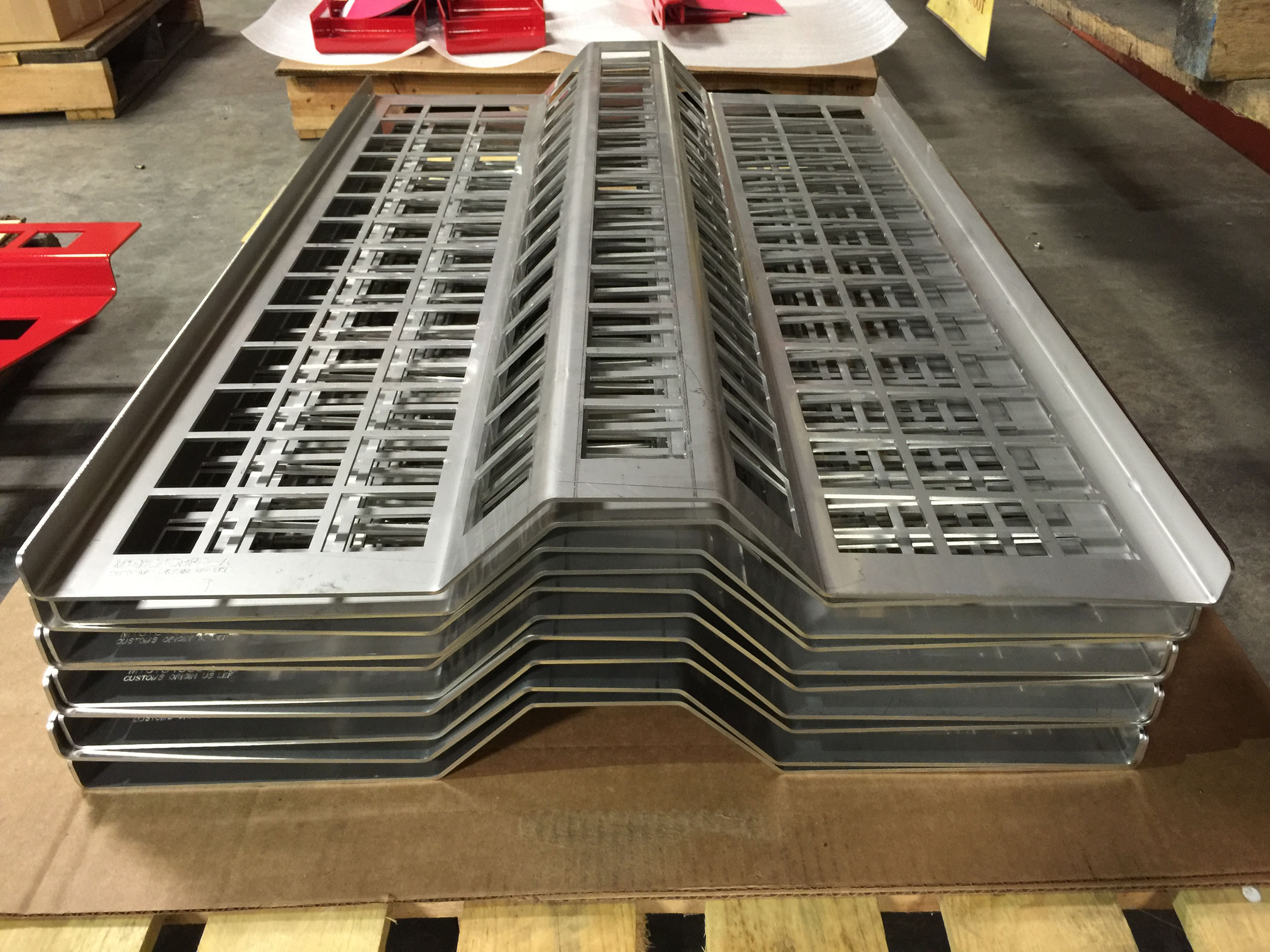

PRESS BRAKE & FORMING

We provide small and large format structural steel rolling, forming and bending for aerospace, architectural, industrial, transportation and commercial uses. Our facilities feature multiple press brakes with a wide range.

MACHINING

We offer a variety of precision machining services. Our in-house machining services will help you drive down costs, shorten lead times and simplify your supply chain.

WELDING

With a long-term focus on providing quality welding services, L.E.F., INC. has made an ongoing commitment to employ AWS-certified welders. Our highly trained, experienced and skilled welders are able to perform a variety of specialized welding services.

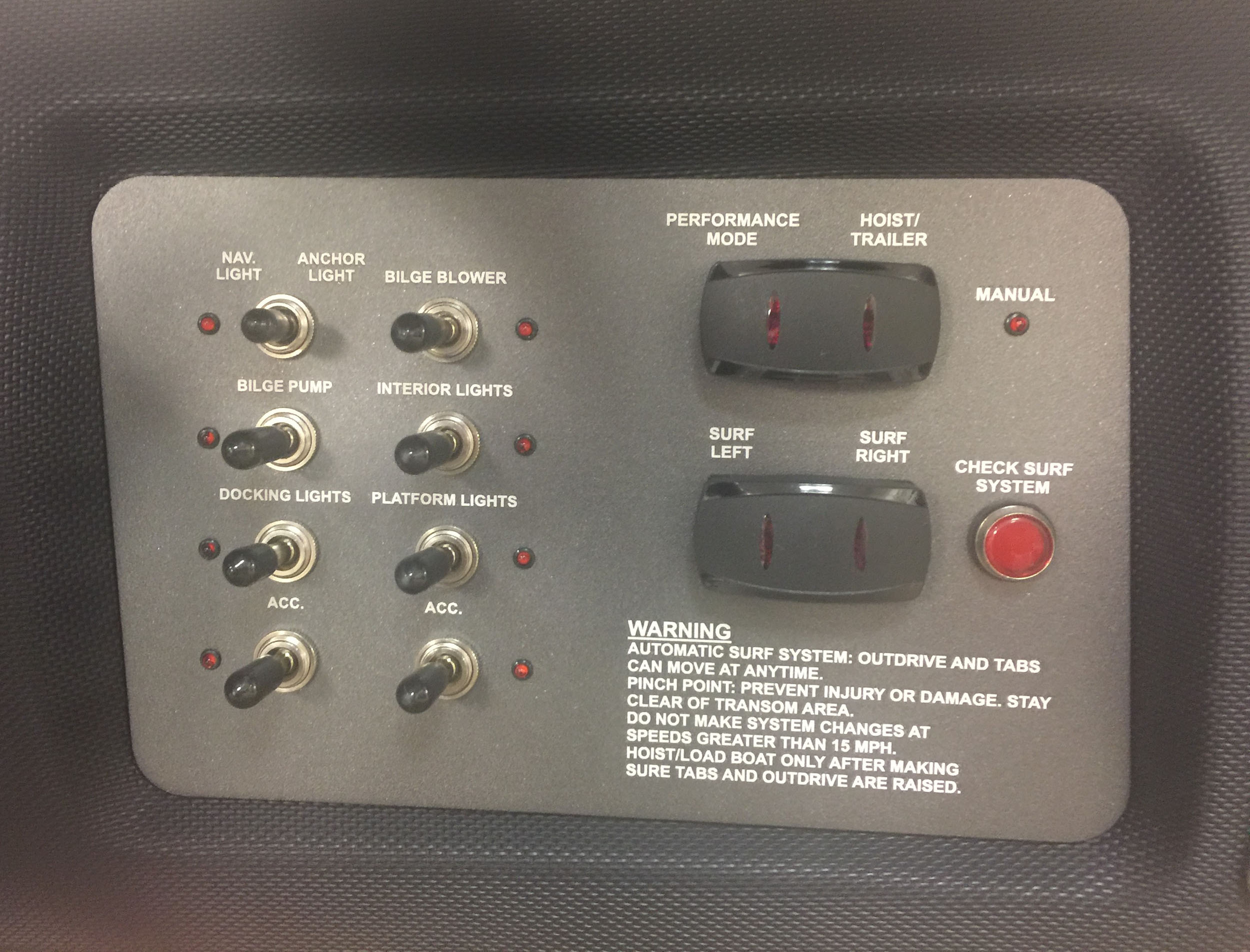

LASER MARKING

L.E.F., INC.. uses C02 and YAG lasers for product marking and engraving. Marking is virtually permanent because it directly interacts with the substrate material. There are a number of effects which can be produced on the work piece.

POWDER COATING

At L.E.F., INC. Powder coating is typically the finalizing process of part production; however, we also offer contract powder coating for parts or products that are customer supplied.

WET PAINT

Industrial wet painting is the traditional method of protecting and aesthetically enhancing components, structures and fabrications. Our wet paint services are effective and have consistent high-quality results.